Overview

PNSL vertical sludge pump is upgraded and developed by our company on the basis of like products at home. The improved PNSL pump has high efficiency, good overflowing condition, abrasion resistance and long service life, and is widely applied to cleaning up and filling sludge in lake and river.

The pump can be combined with high-pressure clean water pump to form a hydraulically excavating and filling machine set for dredging and filling operations. In addition, it can also combined in series with several vertical pumps and a marine-land purpose horizontal sludge pump to form an operation group.

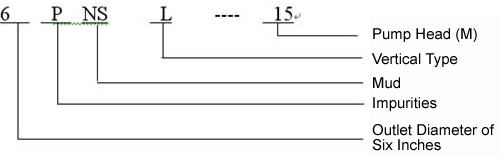

Model Implication:

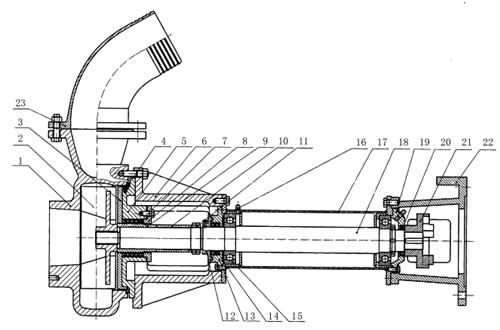

Structural Property:

1.The pump consists of a pump body, an impeller, a guard plate, a motor frame, a bearing assembly and other parts

2.The shaft gland of the pump is sealed by rubber framework oil seals.

3. The rotation direction of the pump is anticlockwise judging from the direction of impeller inlet.

4.An associate impeller is adopted to reduce the back pressure of the impeller and prolong the service life of sealing elements.

5.The overflowing part adopts white wear-resistant cast iron to resist abrasion.

Please see the structural drawing in the attachment.

1、Pump body 2、Impeller 3、 Guard plate of the pump cover 4、Cushion of the pump body 5、Pump cover 6、Pump seat 7、 Oil seal 8、Oil seal gland 9、Shaft housing 10、Positioning sleeve 11、Adjusting nut 12、 Dust preventing end cover 13、Pump coupling 14、Oil seal 15、 Bearing(6313) 16、 Filling cup 17、Middle section 18、Shaft 19、Upper bearing cover 20、Oil seal 21、Pump coupling 22、Motor frame 23、Outlet elbow

Performance Parameter Table

|

Model |

Flow Rate㎡/h |

Pump Lift m |

Speed

r/min |

Shaft Power Kw |

Efficiency % |

Nominal Power Kw |

|

6PNSL-15 |

320 |

15 |

1450 |

18.2 |

72 |

22 |

|

6PNSL-18 |

250 |

18 |

1450 |

18.1 |

72 |

22 |

|

8PNSL-18 |

360 |

18 |

1450 |

21.8 |

72 |

30 |

|

8PNSl-15 |

420 |

15 |

1450 |

23.8 |

72 |

30/37 |

|

4PNSL-15 |

150 |

15 |

1450 |

8.5 |

72 |

15 |

1. The pump is of vertical type, and can be used in a slant way within a certain angle range. And the pump can be fixed on a pontoon, a floating platform or a fixed pedestal.

2.The motor should be provided with a protective cover and the cable interface should be carried out waterproofing process.

3.Oil nozzles at the motor seat and the middle section should be filled with oil once in each operation. The pump body should be maintained once every 300 hours. And the motor should be maintained once every three months.

4.The main machine of the pump should be cleaned and maintained, added with oil to prevent rust, and stored in a dry place when not used. And the main machine of the pump should keep vertical when transported and stored.

Assembly and Disassembly of the Vertical Sludge Pump

1.While disassembly, the order is motor and coupling firstly - pump shell - adjusting nut - guard plate - pump cover - shaft housing - positioning sleeve - pump seat - motor frame - main shaft – bearing finally. All the disassembled metal parts are cleaned and checked.

2.The pump shall be assembled in a reverse order compared with disassembly order. The adjusting nut is used to adjust the clearance between the impeller and the guard plate in the assembly. The main shaft should be rotated by hands to make sure that it is not blocked after assembly. And the bearing chamber and the shaft gland chamber should be filled with lubricating grease during assembly.

Hydraulically Excavating and Filling Machine Set’s Common Troubles and Countermeasures

|

Faults |

Causes |

Countermeasures |

|

The motor has noise when started. |

The motor loses phase. |

Stopping the machine to check the switch contacts and the power cord |

|

Impurities are sucked by the pump to block the rotation. |

Stopping the machine to check and get rid of the blockage |

|

The mechanical friction causes blockage. |

Stopping the machine to overhaul the hand barring |

|

The motor is overloaded. |

The pump works in a low pump lift. |

Adjusting the working status of the pump |

|

There is friction in the pump cavity. |

Adjusting the clearance between the impeller and the front and back covers |

|

The bearing part is overheat. |

The lubricating oil is invalid. |

Cleaning the bearing and changing the oil |

|

The bearing is damaged. |

Replacing the bearing |

|

Mortar on the rotating inlet of the sand pump is bubbled and the pump does not suck the mortar. |

The sandline is blocked. |

Clearing the sandline |

|

The flow passage of the impeller is blocked. |

Clearing the pump cavity |

|

The impeller is severely damaged. |

Replacing the impeller |

|

The water outlet of the sand pump is insufficient. |

The motor rotates reversely. |

Adjusting the connecting lines to change the rotation direction |

|

The impeller is blocked or damaged. |

Removing the impurities, and modifying or replacing the impeller |

|

The pump lift is overhigh and the conveying distance is overlong. |

Connecting the booster pumpin series |

|

The suction nozzle is blocked. |

Removing the blockage |

|

The sand pit is not deep enough and the water inlet is insufficient. |

Making the pump pit properly and guaranteeing the water inlet amount |

|

The front cover is worn and the clearance is overlarge. |

Adjusting the clearance between the front cover and the impeller or replacing the front cover |

|

The high pressure pump has faults. |

Referring to the sand pump fault analysis to exclude the faults |

|