Overview

FGKN sludge pump is non-metal wear-resistant sludge pump developed by our company according to construction conditions of users and based on the performance of EPN sludge pump in use. The overflowing parts of the pump are all made of modern non-metal wear-resistant material, so the pump has strong wear resistance and anti-cavitation performance, is especially suitable for pumping and sending powder sandy soil and conveying sand in long distance. It has the advantages of light weight, convenient disassembly, high efficiency and energy conservation. Since its successful development, the pump has been widely applied to sand pumping and desilting projects in Yellow River valley, Changjiang River valley, seashore poldering project and so on. With its excellent performance, the pump has successively won outstanding prizes in Shandong Yellow River, Yellow River Conservancy Commission, Ministry of Water Resources and so on.

Structural Property

1. The FGKN non-metal wear-resistant sludge pump mainly comprises a pump body, an impeller, a guard plate, a pump cover, a bracket, a bearing assembly and so on.

2. The pump body, the impeller and the guard plate are made of the non-metal wear-resistant material.

3. The pump shaft seal adopts packing seal, and the packing chamber is filled with high-pressure washing clear water, so as to better guarantee the normal operation of the pump.

4. The rotation direction of the pump is anticlockwise if seen from the water inlet, and the outlet of the pump is on the right of the horizontal direction if seen from the water inlet. The water outlet can be adjusted within 360 degrees in field demands.

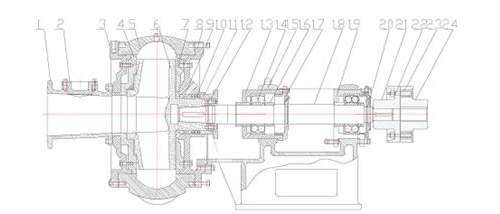

FGKNStructural Sketch Map of the FGKN Sludge Pump

1.water inlet pipe 2.handhole cover 3.front cover 4.front lining board 5.pump shell 6.impeller 7.back lining board 8.back cover 9.packing ring 10.packing 11.gland cover 12.impeller nut 13.front bearing body 14.bearing 15.bearing cavity cover 16.shaft housing 17.front bearing cavity cover 18.pump shaft 19.back bearing cavity 20.back bearing cavity cover 21.pump coupling 22.elastic ring 23.electric connector

Performance Parameters and Curve

|

Model |

Flow Rate Q |

Pump lift H

(m) |

|

Power kw |

Efficiency∩ % |

Suction Stroke(m) |

|

M3/h |

L/s |

Shaft power |

Nominal power |

|

10FGKN-30 |

617 1110 1168 |

171.5 309 324 |

37 31.8 29.1 |

730 |

93.2 130.8 135.1 |

160 |

67 74.8 70 |

6.5 |

|

10FGKN-40 |

870 1100 1250 |

242 306 347 |

43.5 40 36 |

980 |

114.7 122 132.5 |

184 |

69 73 70 |

6 |

|

12FGKN-24 |

1164 1600 1838 |

323 444 511 |

26 24 22.3 |

730 |

126.9 153 169.8 |

184 |

66 70 67 |

6.5 |

|

12FGKN-32 |

1320 1680 1900 |

366 466.7 528 |

34 32.2 29.1 |

900 |

191 219.9 232 |

250 |

65 69 66 |

6.2 |

Installation and Application Instruciton

1、The pump shell, the lining boards and the impeller are made of non-metal material, and should not be forcedly screwed and dragged. The torque of bolts can reach 100N.m.

2、After the sludge pump is fixed in the working field, please check whether the main shaft of the prime mover and the main shaft of the pump are in the same axes first, if no, please perform precise adjustment.

3、 The water inlet and outlet pipes of the pump should be supported to avoid the gravity of the pipes applying to the pump body. The pipes should be installed extending outwards from the suction and discharge flanges, and immediately supported and positioned.

4、 Before starting, please check whether the water inlet and outlet pipes are blocked, fill grease in the front and back bearing cavities, and check whether the packing is full.

5、When working, the sludge pump should be equipped with high pressure clear water pump to convey the clear water the pressure of which is greater than that of the sludge pump to leakproof packing, so as to protect the packing; and the flushing pump should not be closed when the sludge pump works, or the seal parts will be worn soon.

6、Whether the clearance between the impeller and the guard plate is reasonable has big influence on the service life of the sludge pump. If the clearance is not reasonable, the pump generates vibration and noise in operation, and the trans-flux parts are worn soon, therefore, the clearance should meet the drawing requirement when the impeller is replaced; and the clearance can be adjusted through adjusting screws on the back bearing body.

7、The allowable suction stroke of the pump is detected when the pump conveys clear water, and the influence of the sludge on the suction capacity should be considered when the pump pumps the sludge.

8、The assembly and disassembly of the pump should be operated strictly according to the process flow.

9、The shaft and the front and back bearing cavities should be regularly filled with grease.

10、 If there are abnormal vibration and noise and overhigh temperature rise of the bearing in the working of the pump, please stop the machine to check.

Causes of faults and Countermeasures

|

Faults |

Causes |

Solution |

|

Incapability of sucking water of the pump |

Insufficient priming injection, incapability of discharging air in the pump, air leakage of the suction pipe, or big clearance between the front lining board and the impeller |

Continuing to inject priming, checking whether the pipe leaks air, or adjusting the clearance between the front lining board and the impeller |

|

Slow water pumping |

Big clearance between the front lining board and the impeller, incapability of sealing the air by the water outlet pipe, or slow emptying |

Adjusting the clearance, adjusting the water outlet pipe, and installing the vacuum extractor |

|

Small outlet water pressure and flow rate |

Air in the pump, big clearance between the impeller and the front lining board, untight closure of the clutch, wearing of the impeller or the lining boards |

Emptying air in the pump, adjusting the clearance, adjusting clearance between friction plates of the clutch, replacing the impeller or the lining boards |

|

Vibration of the water pump |

Uncoaxiality of the pump shaft and the diesel engine (or the motor), unbalance of the impeller, and damage of the bearing |

Adjusting the coaxiality, testing the balance of the impeller, and replacing the bearing |

|

Quick wear of the journal of the impeller |

Low pump lift of the high pressure water pump, malposition of the packing, and uncoaxiality of the pump shaft and the back cover |

Changing high pressure water pump with high pump lift, replacing the packing, and adjusting the coxiality |

|

Quick wear of the pump |

Poor construction environment (big particles), long conveying distance and long water inlet pipe |

Changing sand field, adding power unit, shortening the length of the water inlet pipe and reducing cavitation |

Application Cases

FGKN non-metal wear-resistance sludge pump has been widely used in the silt dyke of Yellow River. Its market share reaches more than 60%, and with excellent performance, the pump creates a historical record that daily production is 5,400 cubes and monthly production is 130,000 cubes. With the decrease of Yellow River projects, more and more equipment is flooding to harbor engineering construction in the coastal areas, and the outstanding performance of the pump has been verified again.