OverviewEPN dual-purpose horizontal sludge pump used both on board and land is a trash pump and is designed in the reference of two phase flow theory. It has the following models: 250EPN-30, 250EPN-35, 250EPN-40, 350EPN-24, 350EPN-35, 350EPN-45 and 400EPN-22. Through the experiments and operation tests, the pump has the characteristics of high hydraulic efficiency, good wear-resisting property, as well as stable performance when conveying the medium with solid particles. The pump is applicable for dredging inland channel, exploiting seashore, and conveying the slurries with solid particles for coal mine enterprises, mine enterprises, power plants, etc. The concentration of the conveyed medium is more than 40% and the particle size is up to 50mm. In recent years, the pump has been widely used to sand pumping barge and blowing ship for cleaning silt, and used on land for conveying the slurry in long distance.

The pump is applicable for pumping sand for building, powdery sand, silt, tailing slurry, ore, iron sand ore, sediment in sewage treatment works, etc.

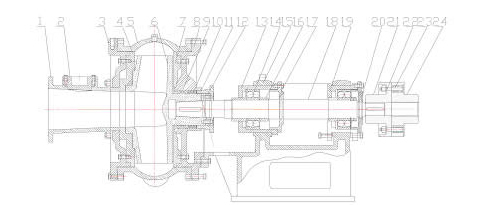

Structural Property1、The EPN sludge pump mainly comprises a pump body, an impeller, a guard plate, a pump cover, a bracket, a bearing assembly and so on.

2、The pump body, the impeller and the guard plate can be made of gray cast-iron, abrasion resistant alloy and non-metal wear resistant material, from which the users can select according to purpose.

3、The pump body, the impeller and the guard plate can be made of gray cast-iron, abrasion resistant alloy and non-metal wear resistant material, from which the users can select according to purpose.

4、The rotation direction of the pump is anticlockwise and the outlet of the pump is on the right from the horizontal direction if judging from the water inlet. The water outlet can be adjusted within 360 degrees according to the demands.

Please see the structural drawing in the attachment.

1.Water Inlet Pipe 2.Handhole Cover 3.Front Cover 4.Front Lining Board 5.Pump Shell 6.Impeller 7.Back Lining Board 8.Back Cover 9.Packing Ring 10.Packing 11.Gland Cover 12.Impeller Nut 13.Front Bearing Body 14.Bearing 15.Bearing Cavity Cover 16.Shaft Housing 17.Front Bearing Cavity Cover 18.Pump Shaft 19.Back Bearing Cavity 20.Back Bearing Cavity Cover 21.Pump Coupling 22.Elastic Ring 23.Electric Connector

Performance Parameters and Curve

Performance Parameters

|

Model |

Flow Rate Q |

Pump Lift H (m) |

Speed n (r/min) |

PowerKw |

Efficiency% |

Suction Stroke (m) |

|

M3/h |

L/s |

Shaft Power |

Nominal Power |

|

250EPN-30 |

617

1110

1168 |

171.5

309

324 |

37

31.8

29.1 |

730 |

93.2

130.8

135.1 |

160 |

66

74

69 |

6.5 |

|

250EPN-35 |

1018

1450

1600 |

283

403

445 |

38

35

31 |

730 |

150.2

180

183.4 |

200 |

70

73.7

72 |

6.5 |

|

250EPN-40 |

870

1100

1250 |

242

306

347 |

43.5

40

36 |

980 |

114.7

122

132.5 |

184 |

66

72

68 |

6 |

|

350EPN-24 |

1164

1600

1838 |

323

444

511 |

26

24

22.3 |

730 |

126.9

153

169.8 |

184 |

64.75

68

65.38 |

6.5 |

|

350EPN-32 |

1320

1680

1900 |

366

466.7

528 |

34

32.2

29.1 |

900 |

191

219.9

232 |

250 |

64

67

64.9 |

6.2 |

|

350EPN-45 |

1600

2200

2527 |

445

611

702 |

48.8

45

41.8 |

600 |

312.5

376.7

418.1 |

400 |

68.14

71.56

68.81 |

6.5 |

|

400EPN-22 |

2000

2200

2500 |

556

611

695 |

24

22

20 |

750 |

190

180

193 |

250 |

69

73

70.5 |

6.5 |

application Indication

1、After the sludge pump is fixed in the working field, please check whether the main shaft of the prime mover and the main shaft of the pump are in the same axes; if no, please perform precise adjustment.

2、The water inlet and outlet pipes of the pump should be supported to avoid pipes compress on the pump body. The pipes should be extended outwards from the suction and discharge flanges during installation, and immediately supported and positioned.

3、When the sludge pump is working, the packing chamber should be filled with high pressure clear water to protect the gland cover assembly. When the main pump is in normal work, the high pressure clear water pump should not be closed. The pressure of the clear water should be greater than the working pressure of the sludge pump. The packing chamber assembly will be worn in a short time if not protected by the high pressure clear water.

4、The suction stroke in the pump performance table refers to cavitation resistive property of the pump in the condition of normal temperature clear water. The inlet pressure of the pump should be positive possibly when the pump is in mud pumping operation. The flow rate and the pump lift of the pump should be affected if the mud contains bigger solid particles, so the medium condition should be taken into consideration in model selection.

5、The clearance between the impeller and the front and back lining boards should be adjusted when the wearing parts such as the impeller and the lining boards are replaced. The size of the axial clearance between the impeller and the lining boards has great influence on the performance and the service life of the pump.

6、Please fill lubricating grease to the bearing parts in right amount in time.

7、If there are abnormal shock and noise and overhigh temperature rise of the bearing in the working of the pump, please stop the machine o check.

Causes of faults and faults excluding methods

|

Faults |

Causes |

Solution |

|

Incapability of sucking water of the pump |

Insufficient priming injection, incapability of discharging air in the pump, air leakage of the suction pipe, or big clearance between the front lining board and the impeller |

Continuing to inject priming, checking whether the pipe leaks air, or adjusting the clearance between the front lining board and the impeller |

|

Slow water pumping |

Big clearance between the front lining board and the impeller, incapability of sealing the air by the water outlet pipe, or slow emptying |

Adjusting the clearance, adjusting the water outlet pipe, and installing the vacuum extractor |

|

Small outlet water pressure and flow rate |

Air in the pump, big clearance between the impeller and the front lining board, untight closure of the clutch, wearing of the impeller or the lining boards |

Emptying air in the pump, adjusting the clearance, adjusting clearance between friction plates of the clutch, replacing the impeller or the lining boards |

|

Vibration of the water pump |

Uncoaxiality of the pump shaft and the diesel engine (or the motor), unbalance of the impeller, and damage of the bearing |

Adjusting the coaxiality, testing the balance of the impeller, and replacing the bearing |

|

Quick wear of the journal of the impeller |

Low pump lift of the high pressure water pump, malposition of the packing, and uncoaxiality of the pump shaft and the back cover |

Changing high pressure water pump with high pump lift, replacing the packing, and adjusting the coxiality |

|

Quick wear of the pump |

Poor construction environment (big particles), long conveying distance and long water inlet pipe |

Changing sand field, adding power unit, shortening the length of the water inlet pipe and reducing cavitation |

Various Matched Units

The sludge pump is widely used in various industries: